|

|

There are several types of electrical switching products. From low cost to high performance, each method serves a part of the market. |

||

|

|

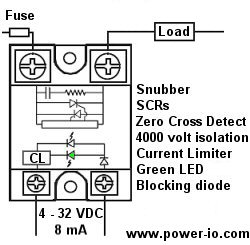

Solid state relays (SSR): The SSR products are usually packaged in the familiar cube shape and are frequently referred to as "hockey puck relays". SSRs can use internal triacs, or the better SSRs will use internal SCRs (a pair of Silicon Controlled Recifiers). Power-io only uses internal SCRs. SSRs turn on and off at the zero crossing mark on a sine wave so electrical surges and noise spikes are greatly reduced. Since there are no moving parts in a SSR, they can be cycled on and off many times per second. SSRs can be an ideal product if you pay attention to the three important application items. Those are: avoid over voltage (surges), over current, and over temperature. For further information, visit: Solid state relay -- extended life and optimum performance. |

|

Power-io

has designed several unique features into our SSR family as part of our Maximum

Surge Survival™ technology. An ideal cycle time for a SSR is often as fast

as 0.2 - 2 seconds and virtually an unlimited number of cycles. SSRs are used

frequently for industrial control of resistive heaters, motor starters (due to

excellent short term amperage surge capability), PC based control applications

(due to minimum control signal input requirements), on/off lighting

applications (zero crossing extends the life of the lamp) and other general

purpose switching applications. When used for heater control, the fast on/off

cycles provide excellent temperature control and this dramatically improves the

heater life due to a reduction in thermal shock. For example: at 20% heater

demand, this may mean 0.05 seconds on, 0.15 seconds off, 0.05 on, .... This is

actually 3 sine waves on, 9 sine waves off, 3 on, 9 off, .... Since you are

switching full sine waves, starting at the zero crossing mark and ending at the

zero crossing mark, there is no noise generated and the power is permitted to

start at zero and then ramp up. The heater stabilizes at a temperature range

and does not fluctuate, thus reducing thermal stress and, therefore, increasing

the heater's life. For information on Power-IO's SSR products, please visit the

"H" hockey puck products at: solid state relay

products |

|

|

Solid state contactors (SSC): When an industrially hardened SSR is assembled onto a properly sized heat sink, the final product is frequently called a solid state contactor. Power-IO uses over-sized internal SCRs (often 20-100% oversized), on a DCB (Direct Copper Bonded ceramic/copper assembly) attached to a thermally optimized heat sink design, finger-safe screw terminations, and an universal mounting bracket. Installation size is minimized by our industry-leading capability that permits you to install the product with NO spaces between products on the same din rail. Therefore, the Power-IO "D" din rail family offers the smallest installed product in the industry. As a finished contactor, the product provides the fastest and most convenient way to install a complete solid state switching product. For more information, please visit: solid-state relays |

|

|

For electric heater control, solid state contactors are typically used with PLCs, PCs, network I/O, or PID controllers that generate the on/off pulsing VAC or VDC control signal. This may be called a time proportional output, TPO, or PWM pulse wave modulation. When used with some PLCs, it may be easier to reduce programming time by using an analog output so Power-IO also has solid state contactors that accept a 4-20mA analog control signal that then gets converted into the appropriate zero crossing output. (4mA=off, 12mA=50%, 16.8mA=80%. 20mA=full on). These have a part number starting with DMA (Din rail, Milliamp input, AC switching). Visit: 4-20 mA input single phase or three phase solid state relays |

||

|

"Intelligent" solid state contactor: The solid state contactors can have additional functions added for diagnostics. The "C Family" contactors have the ability to create an output based upon: SCR problems, load open, fuse open, and thermal problems. In addition, they have the Power-io exclusive feature of monitoring the SCR's health status independent of the control input which is beneficial during machine start-ups. Intelligent contactors are one of the fastest growing segments of power control since they integrate into larger installations, un-staffed applications, and remote monitored applications for on/off power control or on/off motor control. More information is at C Family intelligent solid state contactors. This intelligent model has 3 control input selections:

|

|

|

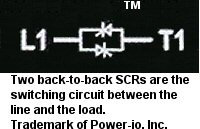

"Zero Crossing" Silicon Controlled Recifier (SCR): The Power-IO solid state relays and solid state contactors use internal zero crossing silicon controlled rectifiers and are sometimes called SCR products, SCR power controllers, SCR power packs, or thyristors. The exclusive way that we activate and deactivate the zero crossing is extremely precise, leading to an exceptionally clean, noise free control mode. When activated by a VAC control signal, we typically do NOT need burden resistors on the control input. Power-IO products are usually for applications from 1-100 amps. There are other SCR vendors who concentrate in SCR applications up to 5000 amps. |

|

|

"Phase Angle" Silicon Controlled Recifier (SCR): A minority of the heater applications use transformer coupled loads or low cold resistance loads. Your heater manufacturer will point out that these loads (such as certain silicon carbide heaters or moly disilicide heaters) require phase angle SCR control plus current limiting, automatic recalculation and correction for voltage fluctuations, partial load imbalance, and/or other features. These units are typically much more expensive but may be required for applications such as molecular beam epitaxy equipment in semi-conductor fab facilities. Phase angle control means the the electrical power is on for part of each sine wave. This permits precise control, but chopping every sine wave creates electrical noise that may impact nearby equipment. For European applications or any country where CE regulations are used, phase angle power controllers usually require customized noise filters that may be as expensive as the phase angle controller that they are attached to. |

||

|

Mosfet Solid State Relay: When switching DC loads, the internal device inside the solid state relay is a mosfet semiconductor (up to 200 VDC) or IGBT (up to 900 VDC). Power-io has a unique technology that permits the rapid 15 Khz switching times for 0-200 VDC applications. Rapid switching is required for PWM dc servo control, automated test equipment applications, and other applications where the need is for instantaneous ON or OFF control. Mosfet solid state relays are also used for DC applications in order to avoid contact bounce or other mechanical problems that are associated with electro-mechanical relays. Most dc loads are somewhat inductive, so it is recommended that you install a diode across the load to avoid EMF problems. For more information visit: mosfet solid state relays |

|

|

Mosfet Solid State Relay: In 2010, the DC switching solid state relays were expanded to include the HDD-E family. The "E" expansions included: faster speeds up to 20 kHz PWM, lighter weight for vehicle or airborne applications, and cooler performance for a decrease in heat sink requirements. For more information visit: mosfet solid state relays |

|

|

Insulated Gate Bipolar Transistor (IGBT): For DC applications from 0-900 VDC, the Power-io HDD-6V15, HDD-6V20E and HDD-9V30E are off-the-shelf IGBT units with our exclusive fast turn ON/OFF/ON/OFF gating control circuit. They are used for DC switching applications up to 900 VDC. These are frequently used for solar applications for DC load control, solar panel disconnect, or battery/dump load toggle selection. For information, please visit: IGBT solid state relays |

|

Other non solid state products include (not sold by Power-io): Mechanical relays or mechanical contactors: The cost of a mechanical relay or mechanical contactor is influenced by amperage and usage. As these increase, so does the price. A mechanical product typically has two ratings: the number of mechanical cycles (a high number) and the number of electrical cycles (a low number). Therefore, mechanical products should be used when the final device is activated infrequently. Mechanical relays are seldom used for heater applications since the cycle time is too slow and the overall product life is often too short. A mechanical device turns on or off when the coil is energized which can result in noise spikes or surges since this is not at the zero crossing point. An ideal cycle time for a mechanical device is often 30-120 seconds or more; and a total on/off cycle life of 50,000 - 250,000 cycles. Some applications (PLC controlled, PC controlled, or sharing the powerline with other nearby computers) will require snubbers across the control terminals to help to suppress the frequent voltage surges upon opening. Mercury contactors or mercury displacement relays (MDR): A mercury contactor uses a pool of mercury, inside a glass sealed tube, to electrically connect the two contacts. This pool may be more than 100 grams of mercury for a single contactor. Since mercury is a cancer causing agent and is banned in many states, countries, or industries; there are restrictions on shipping, storing, or cleaning up if a contactor should leak or explode. A mercury contactor is not a zero crossing device so there will be noise spikes or surges that may affect nearby electrical products or PLCs. An ideal on/off cycle time for a mercury contactor is often 10-20 seconds and 3-8 million overall cycles. Mercury contactors were used frequently for industrial heater control of resistive heaters in the years from 1960 to 2000. When used 24 hours a day in a heater application, there may be 3 million on/off cycles in a single year. Therefore, the mercury contactors might be replaced many times during the life of the machine. Information about the legally required elimination of mercury contactors is online at several locations. Worldwide elimination of mercury is being required by state laws, food industries, environmentalist groups, and more. |

||

|

Power-io

537 Braemar Avenue Naperville, IL 60563

USA |