|

|

As your ambient temperature increases or as your amperage increases, the use of a properly sized heatsink is necessary. Hint: the smaller the "heat sink rating" number, the better the heatsink is at capturing and dissipating the heat. The Power-io heatsinks are the outstanding choice for most applications because they:

|

|

|

Please note: our documented DIN heat ratings are based upon the conservative estimate of being installed in "still air and clipped onto a din rail". Your actual performance will be better than our ratings if: 1) the DIN heatsinks are screwed to a metal subplate (which provides additional heatsinking capability) and/or 2) if there is any airflow in your installation, such as fan cooling. You must use a thermal conduction grease (such as Dow Corning 340™) or a Power-io Thermal Pad in order to achieve the proper heat sinking capability between the SSR and the heatsinks shown below. Hint: Solid state relays are

semiconductor devices that generate heat in proportion to the quantity of amps

being switched. Heat sinks capture that thermal rise and dissipate it. Heat

sinks are rated by a ºC/W number that represents: for every watt of heat

generated, the solid state relay will increase by xºC. For example: if you

put 30 watts of heat on a 2ºC/W heat sink, the solid state relay's

internal SCR dies will rise 60ºC (30 x 2ºC) above the ambient

temperature. Therefore, the lower the °C/W rating, the more

aggressively the heat sink captures and dissipates the heat. See our Power-IO

data bulletins

(AC

switching SSR) or

(DC

switching SSR) for thermal charts for your particular application. It is

important that you use a properly sized heat sink or else the SSR product will

be permanently damaged. |

||

|

HEATSK-DIN-2.0 Perfect size -- smallest outside dimensions while providing optimized heatsink capability. Uses about the same panel space as the just the SSR while providing the proper heatsink capability that is required for the majority of "typical" 3-25 amp applications.

|

|

|

HEATSK-DIN-1.0U Universal Mounting Bracket and Compact size -- small width dimensions while providing optimized heatsink capability. An engineering-optimized design uses the minimum amount of installation space while providing the proper heatsink capability that is required for the majority of "typical" 20 - 60 amp applications.

|

|

|

Ultra Power Cooler™ (Trademark of POWER-IO) The UPC Heat Sink family represents the the work horse -- any amperage application, at almost any ambient temperature, in any high density installation! |

||

|

|

This Ultra Power Cooler is "large face size" heat sink or a fan assisted heat sink design. This permits better heat dissipation, while still occupying a very small installation area. Ideal for the higher amperage SSRs, custom SSR or IGBT applications, warm ambient temperature installations, or high density installations that have restricted free air flow.

|

|

|

Only 3.15 inches (80mm) wide |

Ultra Power Cooler™ This Ultra Power Cooler is a fan assisted heat sink design for narrow applications. The 80mm size permits great heat dissipation, while still occupying a very small installation area. Ideal for industrial applications where mechanical or mercury contactors were installed, which often only permit products that are less than 4 inches wide.

|

|

|

|

Traditional SSR Heat Sink The traditional heat sink designs are still available for applications where there is a very large area for the installation. The HEATSK-1.5-SM is 4.75 inches wide and 3 inches long. It is rated at 1.5ºC/W which is for typical 5-40 amp applications. The HEATSK-1.0-SM is 4.75 inches wide and 5.5 inches long. It is rated at 1.0ºC/W which is for typical 25-60 amp applications. Both heatsinks are attached by screws to the electrical cabinet.

|

|

|

|

Thermal Transfer Pad This high performance dry pad looks like a piece of black aluminum foil. It is sandwiched between the relay and the heat sink. When the relay is activated, the relay’s heat changes the dry pad into the optimal amount of thermal grease. Quick, easy, clean. Just the “right amount” to ensure the best thermal transfer characteristics. When installing the thermal pad, ensure that you fully tighten the two installation screws. Recommended torque: 20 - 25 inch pounds. |

|

|

|

Mounting Screws (relay to heat sink) The recommended mounting screws are Metric M4 or 8-32 screws. We typically use phillips head screws but customers can use other screw head styles that match your local installation equipment. Our part number is: SCRW,Metric_M4x14mm(pair of: screws, M4, 14mm long,phillips head) for our standard HEATSK-DIN-2.0 or 1.0U heat sinks. Our part number is: SCRW,8/32X1/2PH (pair of: screws, 8-32, 1/2 inch long, phillips head) for our standard UPC heat sinks. |

|

|

|

MOVs A MOV adds a fourth layer of voltage surge survival to our trademarked Maximum Surge Survival™ design. The MOV is beneficial if the application is exposed to a high quantity of repetitive AC surges, or to very high amplitude AC surges. A MOV is strongly encouraged on Power-IO motor starters since a motor's coil is a large voltage surge generator (inductive flyback). By design, the Maximum Surge Survival circuit offers the first three strong layers of defense, so the MOV is considered additional protection. |

|

|

Pre-installed labor If you wish, we can pre-assemble exactly what you order. First, order your relay, MOV (if desired), and heat sink. This service is a single line item that will: add one thermal pad or thermal grease, add a pair of installation screws, assemble the unit, and torque the installation screws to 20-25 inch pounds. The cost is per SSR. |

||

|

Previous models which have been discontinued and are no longer available |

||

|

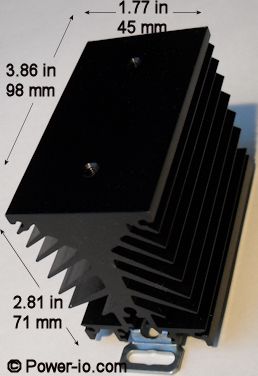

HEATSK-DIN-1.6 Perfect size -- smallest outside dimensions while providing optimized heatsink capability. Uses about the same panel space as the just the SSR while providing the proper heatsink capability that is required for the majority of "typical" 5 - 40 amp applications.

|

|

|

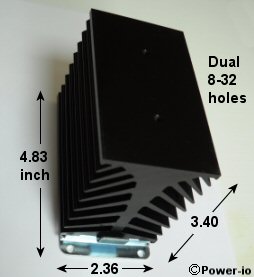

HEATSK-DIN-1.0 Compact size -- small width dimensions while providing optimized heatsink capability. An engineering-optimized design uses the minimum amount of installation space while providing the proper heatsink capability that is required for the majority of "typical" 25 - 60 amp applications.

|

|

|

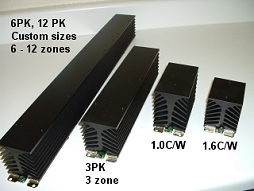

HEATSK-3PK-1.2 or

HEATSK-6PK-1.2 The "6 Pack" or the "3 Pack" have a small width dimension while providing excellent heatsink capability. While only 2.4 inches wide and 22 inches high (6 Pack) or 11 inches (3 Pack), these multi-zone heat sinks can be populated with several of the "H" hockey puck relays. Ideal for: several single phase zones, three phase zones, and similar applications.

|

|

|

HEATSK-DIN-1.0D or HEATSK-DIN-1.0S Compact size -- small width dimensions while providing optimized heatsink capability. An engineering-optimized design uses the minimum amount of installation space while providing the proper heatsink capability that is required for the majority of "typical" 20 - 60 amp applications.

|

|

|

|

||